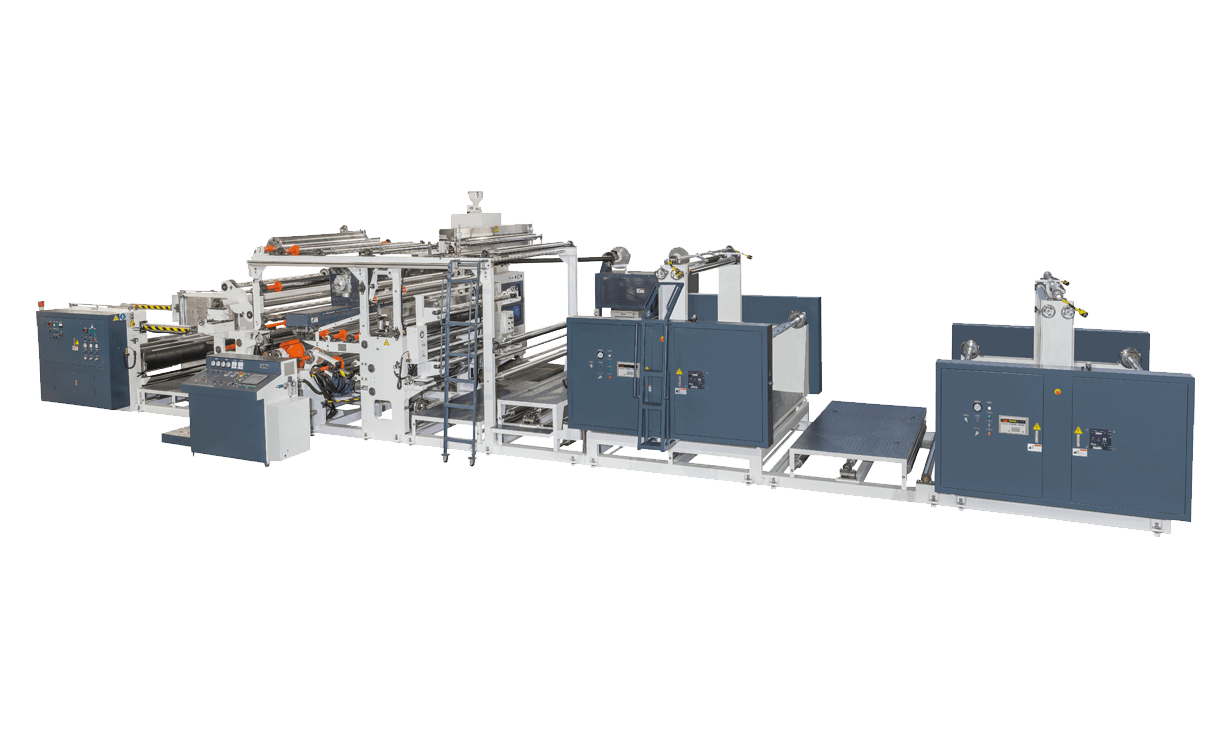

To sandwich laminate two substrates material together, one substrate material single side coating, one substrate with double side coating, or strip(section) lamination for two substrates to be tear off easily for further recycle, the thickness of lamination can be 6 micron to 60 micron, working width can be 2mm to 6000mm, with higher extrusion capacity for higher running speed, the maximum machine speed can catch 200m/min.

It is fully automatic control by screen touch panel, and can upgrade to include mirror or embossing surface cooling roller, turn bar, recycling system, cooling system, primer coater, surface treatment device…etc.

Application can be woven sack, cement bag, onion bag, paper cup / milk box, non-woven fabric..etc.

Successful lamination machine installed countries:

Taiwan, Indonesia, Philippines, China, Morocco, Argentina, Thailand, Paraguay, mexico, Pakistan, Korea, South Africa, Ecuador, Chile, Bolivia, Tunisia, Brazil, USA, Egypt, Bangladesh, Myanmar, Russia, Turkey, Costa Rica, Vietnam, Algeria, Nigeria, Ivory Coast, India, Uzbekistan, Sudan, Kazakh, Finland, Zimbabwe, Morocco, El Salvado, Honduras, Uruguay, Tanzania